Carbon Footprint

- SOLAR ENERGY -We have installed Solar Panel Board at our facility for generation of electricity from solar panels. This is very effective and has a positive outcome for our facility. For remote monitoring of total units generated; the system is connected with a pro log data logger installed at our facility. The review of energy consumption and conservation is monitored on daily/weekly/monthly frequency. Daily we get around 60 Kwh of electricity generated through the solar plant which is directly connected to our main grid.

- POWER SAVING MOTORS IN UBT MACHINE – To reduce the energy consumption Power Saving Motors/machines have been installed which are in major part of the production process. The conventional belt drive and clutch motors have been totally removed and machine with servo motors have been installed. This has reduced the energy usage by 25%. In the year 2015 we have procured 168 such machines worth INR 64 lakhs .

- LED LIGHTS – We have installed LED lights in all the portable cutting machines and stitching machines to get the desired lux levels for ease of work with a very minimal energy usage. All the machines are fitted with topical LED lights which gives desired lumination (Lux levels) for the area and the activity and we conserve a considerable amount of energy in comparison to conventional lights.

- SOLAR WATER HEATER – We have installed Solar water Heater on the factory building which is used in ironing section for Steam irons to readily provide warm water for production of steam. It pre-heats the water required for ironing boilers to 75 degrees, while only the remaining 25 degrees is done by conventional power. Heating water for boiler from room temperature would require at least 40% more power and 20% more time.

- ATRIUMS & VENTILATORS – Atriums are provided on the stitching floor, enabling us to keep lights completely off on an average sunny day. We have installed forced ventilators and on our terrace roof which keeps the temperature normal in summer seasons and we are blessed to be on the just fifty meters from river Ganges and breeze from their enables us to even switch off fans on normal days.

- BICYCLES & POOL TRANSPORT SERVICES– More than 70% of the workforce come on bicycles which they bought from taking interest free loans from the company and rest of the workers come on chartered pool service provided by the company on very subsidised rates.

- DIGITISATION -80% of our internal documentation has been digitized. This paperless reports and communications is not only saving our environment but has also increased our efficiency .

- REDUCTION IN CARBON FOOTPRINTS BY INSTALLING ROBOTIC MACHINES – We have installed many specialised robotic machines which has increased our efficiency thereby saving on energy usage and carbon footprint

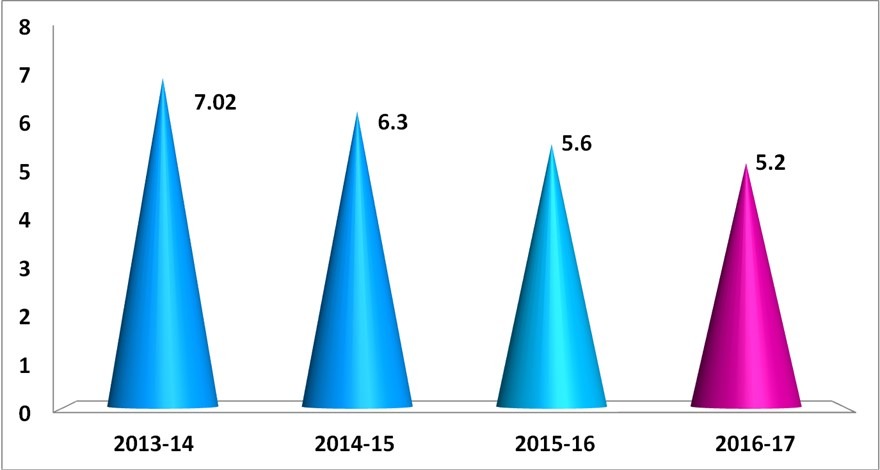

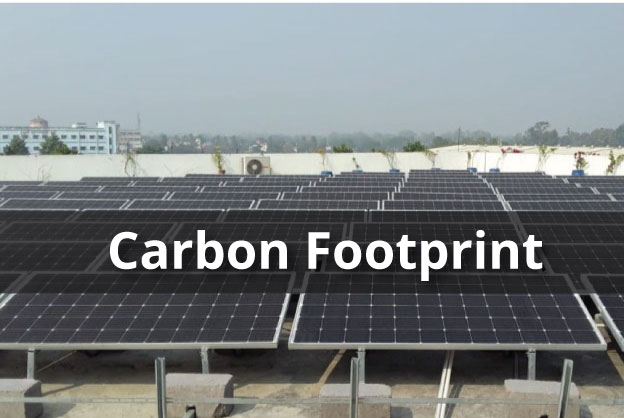

Environmental Initiatives (Electricity Usage)

Water Usage

In our organization water is largely used for domestic purposes only. In processes water is being used for producing steam for ironing purposes and for cleaning of screens used in printing. To conserve the usage of water we use rain water harvesting and the rain water is connected to our main tank through a filtration/treating unit and is used for all the domestic and production process purposes. We also have an ETP which treats the water from screen washing. We use only GOTS approved paints . Organic paints being non hazardous, the treated water from ETP is used for gardening purposes.

SPECIFIC WATER CONSUMPTION TREND IN LITRES